How To Make a Wire Harness

👉 Make sure you've signed up for the Free Course all about Sequential LED designs, which will ALL need the harness I'm breaking down for you here.

There's something about wiring that just freaks people out.

I think many people who learned about cars from their dads, or older mentors, were warned never to mess with the wiring.

The reality is, making things with wires, and wiring itself, isn't very difficult, but much like diagnosing and fixing an overheating motor, it can be hard to trace down problems in an existing system.

SO, let's break down this video into components, make them bite size and not so scary, and before you know it, you'll be able to bang out a wire harness of your own in no time!

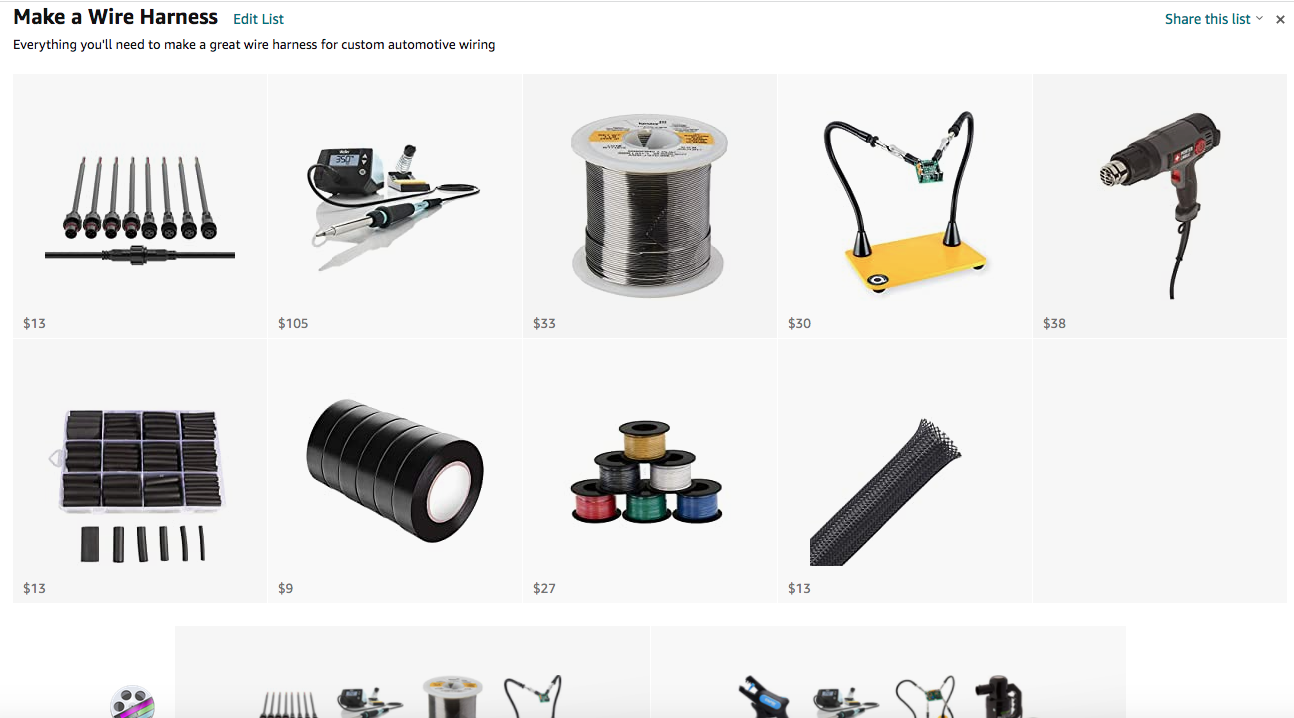

👉 CLICK HERE for everything listed on my Amazon Shop:As an Amazon Associate I earn from qualifying purchases.

So we have our materials:

- 18 awg Primary Wire

- Heat Shrink Tubing

- Braided Wire Loom

- BTF Lighting Connectors

- Electric Tape

- Solder

Our Tools:

- Soldering Station

- QuadHands

- Heat Gun

- Wire Strippers

- Scissors

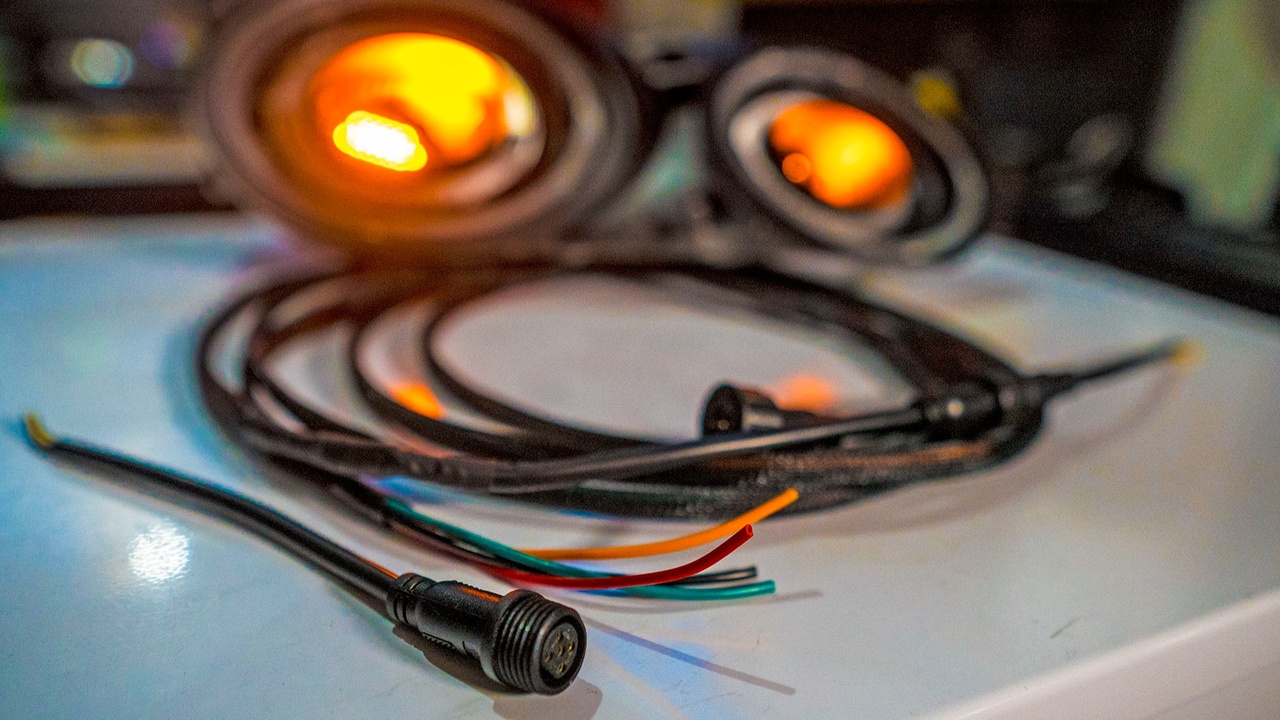

We're going to start out by just cutting the wires to length.

In my case, I'm building a simple harness for a Nissan GTR that has the battery under the hood, near the firewall on the passenger side.

That means I need one section of wire to reach from the battery tray, to the Passenger Headlight, which I cut at about 5 ft.

We also need to run wires over to the Drivers side headlight, which requires about 7 ft. of wire.

The harness building process at it's basic form, is just combining those two groups of wires, stripping the ends and twisting them together, then adding the BTF Lighting Connectors at each end of the 7 ft. wires.

When we're done, we'll have multiple wires at the battery, which we can connect to a controller, or multiple controllers. That means we can send the function of those controllers out to both headlights, or side markers, or fog lights, or DRLs, or Turn Signals, etc.

We can send power and ground anywhere we want it, because of the wire harness, and we can easily connect our custom lights to this harness after it's installed on the vehicle.

Nothing worse than needing to weed through a rats nest of wires with 5 different connectors that look the same, but power different things (things that could be damaged if plugged into the wrong connector).

Especially if you need to remove a custom light with tons of plugs and wires coming out of it.

This is the way.

How Much for Custom Lights?

People ask me that question about Custom Lights just about every single day. So I put this👇 together for YOU!

FREE GUIDE: Find out How Much, while saving Money and Frustration:

5 Keys to Getting Custom Lights

(Built the Right Way).